1,Introduction to Full Automatic Block Production Lines.

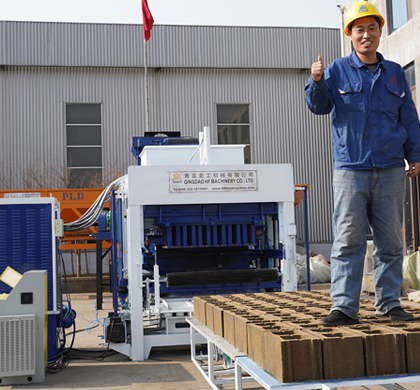

Full automatic block production lines are the future of the construction industry.

They are able to produce blocks with much higher productivity than the traditional hand-made blocks.

The full automatic block production line is made up by a series of machines that work together to produce blocks at an astonishing rate.

The whole process is automatic, so there are no human operators on site.

The machine starts by crushing stones into small pieces, and it mixes them with sand and water in order to form a slurry ,

then poured into molds and dried before being cut into blocks.

2,What are the Main Parts of a Full Automatic Block Production Line?

Main parts of a full automatic block production line as follows:

1). Production line- it used to produce all kind of blocks

2). Feeding system- it can feed materials to the automatic block machine continuously and automatically

3). Cutting system- it can cut blocks into required size automatically and continuously

4).Automatic Finer Cart Control System-it used to collect pallets and transfer them to the curing chambes.

It returns with cured products from another chamber, placing them in the Pallet lowerator.

This system is controlled by computer program, so it can produce with high- efficiency by full automatically.

This system adopts automatic or manual control mode.

And also it has the frequency converter to ensure the blocks with good quality, high density and beautiful look, could be unmanned operation.

3,Advantages of Full Automatic Block Production Lines

1. Reduce work-related injuries.

2. Improve quality of materials.

3. Enlarge productivity.

4. Lessen downtime and waiting time for workers to deliver raw materials.

5. Decrease need for skilled labor from specialized technican on site.

en

en Search

Search